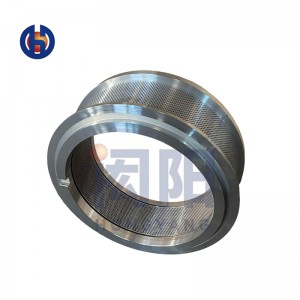

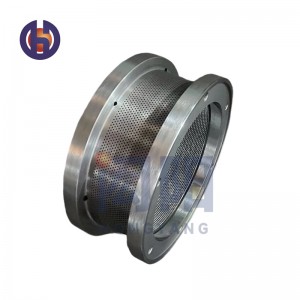

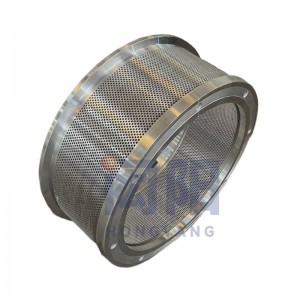

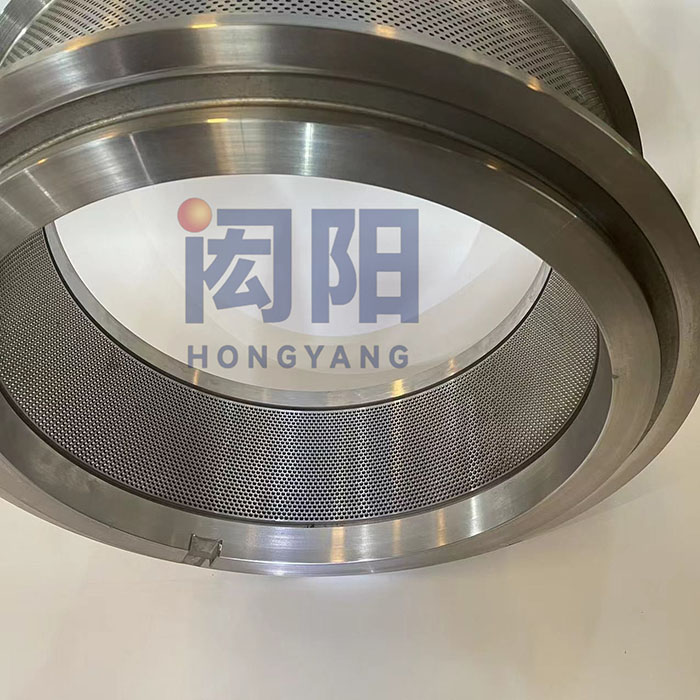

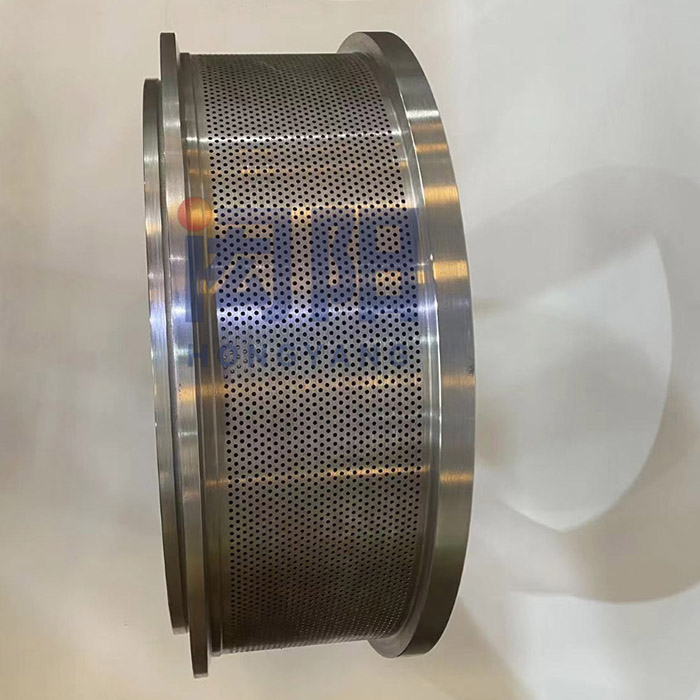

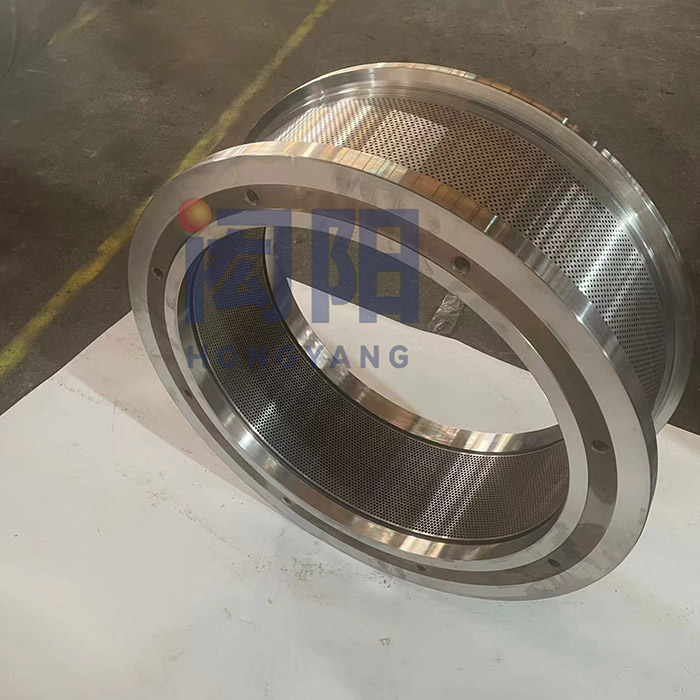

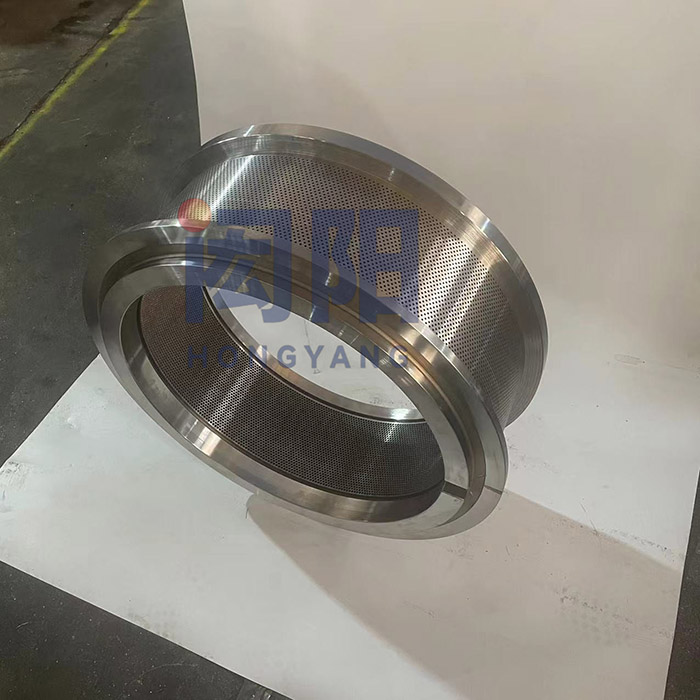

CPM3020 CPM3020-6 Pellet Ring Die

CPM Series

|

Series |

Model |

Size(mm) |

Working face size(mm) |

|

CPM |

3016-4 |

559*406*190 |

116 |

|

CPM |

3016-5 |

559*406*212 |

138 |

|

CPM |

3020-6 |

660*508*238 |

156 |

|

CPM |

3020-7 |

660*508*264 |

181 |

|

CPM |

3022-6 |

775*572*270 |

155 |

|

CPM |

3022-8 |

775*572*324.5 |

208 |

|

CPM |

7726-6 |

890*673*325 |

180 |

|

CPM |

7726-8 |

890*673*388 |

238 |

|

CPM |

7932-9 |

1022.5*826.5*398 |

240 |

|

CPM |

7932-11 |

1027*825*455.5 |

275 |

|

CPM |

7932-12 |

1026.5*828.5*508 |

310.2 |

|

CPM |

7730SW |

||

|

CPM |

2016 |

||

|

CPM |

7712 |

Product Installation

The general way to install a pellet mill ring die is as follows:

1. First, make sure that the granulator is turned off and the power is disconnected. Safety should always be a top priority.

2. Remove the old ring die from the pellet mill. Depending on your granulator model, this may require unscrewing some bolts or releasing some locking mechanisms.

3. Thoroughly clean the cavity to remove any debris and old material that may have accumulated. This ensures that the new ring die is properly seated.

4. Install the new ring die on the pellet mill. Pass the granulator shaft through the center hole of the ring die and position it correctly in the granulator chamber. The ring die must be perfectly aligned with the granulator rolls and securely secured with bolts and locking mechanisms.

5. Make sure the ring die is properly lubricated. Check the manufacturer's instructions to find out the recommended method for lubricating ring dies and make sure the lubricant is applied in the correct amount and in the correct location.

6. Check whether the alignment of the granulator is correct. The ring die must be at the same level as the rollers of the granulator, and the gap between the rollers and the ring die should be minimal.

7. Finally, turn on the pellet mill and run it for a short period of time to check that the new ring die is running smoothly and producing good-quality pellets.

Remember that ring die setup is critical to the quality and longevity of your pellet production operation. If you are unsure about the installation process or have any questions, it is best to contact a professional technician to assist you.

Product Display

Pellet Die model we can customize:CPM, Buhler, CPP, OGM, Zhengchang(SZLH/MZLH), Amandus Kahl, Muyang(MUZL), Yulong(XGJ), AWILA,PTN, Andritz Sprout, Matador, Paladin, Sogem, Van Arssen, Yemmak, Promill; etc. We can customize for you according to your drawing.